Optimización del esquema de bodegas utilizadas para el almacenamiento de materiales de construcción y reparación naval

DOI:

https://doi.org/10.25043/19098642.59Palabras clave:

bodega, almacenamiento, modelos de rosenblatt y roll, buquesResumen

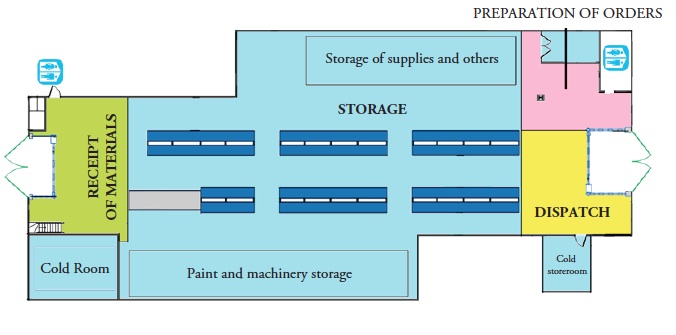

El articulo muestra la evaluación de la aplicación de modelos para mejorar la eficiencia en el manejo de bodegas utilizadas en astilleros, centrada en actividades derecolección, embalaje y envío, soportada entre otras en la propuesta de Rosenblatt y Roll (1984) para la optimización del diseño para el almacenamiento y manejo de los materiales necesarios para la construcción y reparación de buques. Además de proponerla mejor distribución física para el almacenamiento de las mercancías, el modelo busca minimizar tres tipos de costos: costos asociados a la inversión inicial (construcción y de mantenimiento), un costo de escasez y los costos asociados con las políticas de almacenamiento. El diseño óptimo se desarrolla con una combinación de optimización analítica y técnicas de simulación.Descargas

Referencias bibliográficas

BASSAN, Y., ROLL, Y., ROSENBLATT, M.J., 1980. Internal layout design of a warehouse. AIIE Transactions 12 (4), 317–322.

BERRY, J.R., 1968. Elements of warehouse layout. International Journal of Production Research 7 (2), 105–121.

BOZER, Y.A., WHITE, J.A., 1984. Travel-time models for automated storage/retrieval systems. IIE Transactions 16, 329–338.

ELDEMIR, F., GRAVES, R.J., MALMBORG, C.J., 2004. New cycle time and space estimation models for automated storage and retrieval system conceptualization. International Journal of Production Research 42 (22), 4767–4783.

FRANCIS, R.L., “On some problems of rectangular warehouse design and layout,” Jou. Of Ind. Eng., Vol. 18 (1967), 595 -604.

FRANCIS, R.L., 1967. On some problems of rectangular warehouse design and layout. The Journal of Industrial Engineering 18, 595– 604.

GU, GOETSCHALCKX AND MCGINNIS (2010) Research on warehouse design and performance evaluation: A comprehensive review European Journal of Operational Research 203 (2010) 539–549.

HERAGU, S.S., DU, L., MANTEL, R.J., SCHUUR, P.C., 2005. Mathematical model for warehouse design and product allocation. International Journal of Production Research 43 (2), 327–338.

HAUSMAN, W.H., SCHWARZ, L.B., GRAVES, S.C., 1976. Optimal storage assignment in automatic warehousing systems. Management Science 22 (6), 629–638.

JOHNSON, M.E., BRANDEAU, M.L., 1996. Stochastic modeling for automated material handling system design and control. Transportation Science 30 (4), 330–350.

LARSON, T.N., MARCH, H., KUSIAK, A., 1997. A heuristic approach to warehouse layout with class based storage. IIE Transactions 29, 337–348.

PARK, Y.H., WEBSTER, D.B., 1989. Design of class-based storage racks for minimizing travel time in a three dimensional storage system. International Journal of Production Research 27 (9), 1589–1601.

ROBERTS, S.D., REED, R., 1972. Optimal warehouse bay configurations. AIIETransactions 4 (3), 178–185.

ROODBERGEN, K.J., 2001. Layout and routing methods for warehouses. Ph.D. thesis, RSM Erasmus University, the Netherlands.

ROSENBLATT, M.J., ROLL, Y., 1984. Warehouse design with storage policy considerations. International Journal of Production.

SARKER, B.R., BABU, P.S., 1995. Travel time models in automated storage/retrieval systems: A critical review. International Journal of Production Economics 40, 173–184.

TOMPKINS, J.A., WHITE, J.A., BOZER, Y.A., FRAZELLE, E.H., TANCHOCO, J.M.A., 2003. Facilities Planning. John Wiley & Sons, NJ.

VAN den BERG, J.P., 1999. A literature survey on planning and control of warehousing systems. IIE Transactions 31, 751–762.

WHITE, J.A., FRANCIS, R.L., 1971. Normative models for some warehouse sizing problems. AIIE Transactions 9 (3), 185–190.

Descargas

Publicado

Número

Sección

Licencia

The authors who publish in this Journal certify that:

- The work submitted for publication in The Ship Science and Technology journal, was written by the author, given that its content is the product of his/her direct intellectual contribution.

- All data and references to material already published are duly identified with their respective credits and are included in the bibliographic notes and quotations highlighted as such.

- All materials submitted for publication are completely free of copyrights; consequently, the author accepts responsibility for any lawsuit or claim related with Intellectual Property Rights thereof, Exonerating of responsibility to The Science and Technology for the Development of Naval, Maritime, and Riverine Industry Corporation, COTECMAR.

- In the event that the article is chosen for publication by The Ship Science and Technology journal, the author state that he/she totally transfers reproduction rights of such to The Science and Technology for the Development of Naval, Maritime, and Riverine Industry Corporation, COTECMAR.

- The authors retain the copyright and transfer to COTECMAR the right of publication and reproduction of the work which will be simultaneously subject to the Creative Commons Attribution License (CC - BY), which allows the license to copy, distribute, display and represent the work and to make derivative works as long as it recognizes and cites the work in the manner specified by the author or licensor.

- For more information about the Creative Commons Attribution License (CC -BY) and his use and scope, please visit the following web page https://creativecommons.org/licenses/by-sa/4.0/legalcode