Soldabilidad de un acero microaleado utilizando el proceso Smaw y metal de aporte ferrítico de alta resistencia

Palabras clave:

soldabilidad, aceros para blindajes, ensayo de severidad térmica controlada, ensayos de placas en H, metal de aporte ferríticoResumen

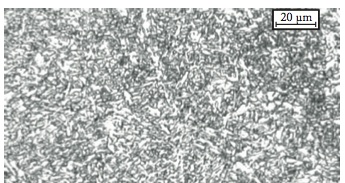

En esta investigación se estudió la soldabilidad de uniones de un acero templado y revenido para blindajes del tipo MIL A46100 (Fe; 0,28% C; 0,30% Cr; 0,24% Mo y 0,20% Ni), usando metal de aporte AWS E11018M, y el proceso Smaw (soldadura al arco eléctrico con electrodo revestido), a través de relaciones generadas entre microestructura, variables del proceso y propiedades mecánicas (tracción, impacto Charpy V y microdurezas), en juntas de soldadura. Asimismo se evaluó el agrietamiento en frío a través de dos ensayos (severidad térmica controlada y placa H), y el desempeño en servicio (balístico) de las mismas, obtenidas al practicar uniones con dos entradas de calor, denominadas alta y baja. Se estableció la incidencia del aporte calórico sobre las propiedades y el desempeño.Descargas

Referencias bibliográficas

Ade. F. (1991, September), Ballistic qualification of armor steel weldments. Welding journal. pp. 53-58.

Akselsen, O. M. Ø. Grong, N. Ryum and N. Christensen. (1986, September), HAZ grain growth mechanisms in welding of low carbon microalloyed steels. Acta Metallurgica, vol. 34, Issue 9, pp. 1807-1815.

Andersen, I.; A. O. Kluken and Ø. Grong (1993, November), The origin of microstructure and hardness gradients within As-deposited steel weld metals. Welding Journal, pp. 63-68.

ANSI/AWS B4.0-98: “Standard Methods for Mechanical

Testing of Welds” (1997, December), American Welding Society, pp. 62-64.

Ballistic testing of armor weldments. Test Ope-rations Procedure (TOP) 2-2-711. WU A268445. January 1994.

Código ASME IX, Sección II parte C: Electrodos y materiales de aporte. Norma AWS A5.5-81.

David L. Olson; Stephen Liu & Glen R. Edwards. Role of solidification on HSLA steel weld metal chemistry. Proceedings of HSLA weldments. 1990.

Gangopadhyay, K. and P. K. Das. (1989, April) Selection of electrodes for welding of armor plates and procedure for approval. Indian welding Journal, pp. 483-487.

Losz, J. M. and K.D. Challenger. HAZ Microstructures in HSLA steel Weldments.

Madhusudhan Reddy G. and Mohandas T. Ballistic performance of high strength low-alloy steel weldments. Journal of materials processing technology 57 (1994), pp. 23-30.

Madhusudhan Reddy G., Mohandas T. and K. K. Papukutty. Effect of welding process on the ballistic performance of high strength low alloy steel weldments. Journal of materials processing technology 74 (1998), pp. 27-35.

Madhusudhan Reddy G. & Mohandas T. Ballistic performance of high strength low-alloy steel weldments. Journal of materials processing techno-logy 57 (1994), pp. 23-30.

MIL STD 1941 “Ballistic Qualification of armor steel welding”.

Mohandas T., Madhusudhan Reddy G. and B. Satish Kumar. (1999) Heat-affected zone softening in high strength low-alloy steels. Journal of mate-rials processing technology 88, pp. 284-294.

N. Yurioka. Weldability of modern high strength steels. First United States-Japan Symposium on Advances in welding metallurgy. Junio 1990, pp. 51-64.

Sindo Kou. (2003) Welding Metallurgy 2nd edition, Cap. 17 pp. 405-407.

Surian E. S. y L. A. de Vedia. All-Weld-Metal Design for AWS E10018M, E11018M and E12018M Type Electrodes. Welding Journal. 217-s-228-s Junio 1999.

Standard NIJ 0108.01: Ballistic Resistant Protective

materials. U.S. Department of Justice. National Institute of Justice.

Vercesi, Jose& Estela S. Surian. The effect of welding parameters on high strength SMAW All-weld metal Part 1: AWS E11018M. Welding Journal. June 1996. 191s-196s.

Número

Sección

Licencia

The authors who publish in this Journal certify that:

- The work submitted for publication in The Ship Science and Technology journal, was written by the author, given that its content is the product of his/her direct intellectual contribution.

- All data and references to material already published are duly identified with their respective credits and are included in the bibliographic notes and quotations highlighted as such.

- All materials submitted for publication are completely free of copyrights; consequently, the author accepts responsibility for any lawsuit or claim related with Intellectual Property Rights thereof, Exonerating of responsibility to The Science and Technology for the Development of Naval, Maritime, and Riverine Industry Corporation, COTECMAR.

- In the event that the article is chosen for publication by The Ship Science and Technology journal, the author state that he/she totally transfers reproduction rights of such to The Science and Technology for the Development of Naval, Maritime, and Riverine Industry Corporation, COTECMAR.

- The authors retain the copyright and transfer to COTECMAR the right of publication and reproduction of the work which will be simultaneously subject to the Creative Commons Attribution License (CC - BY), which allows the license to copy, distribute, display and represent the work and to make derivative works as long as it recognizes and cites the work in the manner specified by the author or licensor.

- For more information about the Creative Commons Attribution License (CC -BY) and his use and scope, please visit the following web page https://creativecommons.org/licenses/by-sa/4.0/legalcode